PURe printing inks

are pure and sustainable.

The PURe ink system is the purest and most sustainable one currently available. It covers the entire colour range including PURe varnishes and PURe metallic inks.

PURe® is also available for inside printing of food packaging (direct contact). These offset inks can be used to produce migration-compliant food packaging. However, for reasons of rub resistance, we always recommend coating with PUReDFC Varnish.

Test report cardboard printed without varnish

Download report as a PDF file (German language)

Test report cardboard printed and varnished

Download report as a PDF file (German language)

PURe characteristics compared to other ink systems

PURe additives

perfectly match to the ink system.

In addition to the printing inks, the PURe ink system contains a range of additives:

PURe Fount — Fountain Solution

PURe Clean — Cleaning Agent

PURe Protect — Roller Protection Oil

PURe Wash — Washing Agent

PURe AntiCalc — Roller Softening Agent

PURe RollerClean — Roller Cleaning Paste

PURe Dilute — Diluting Agent

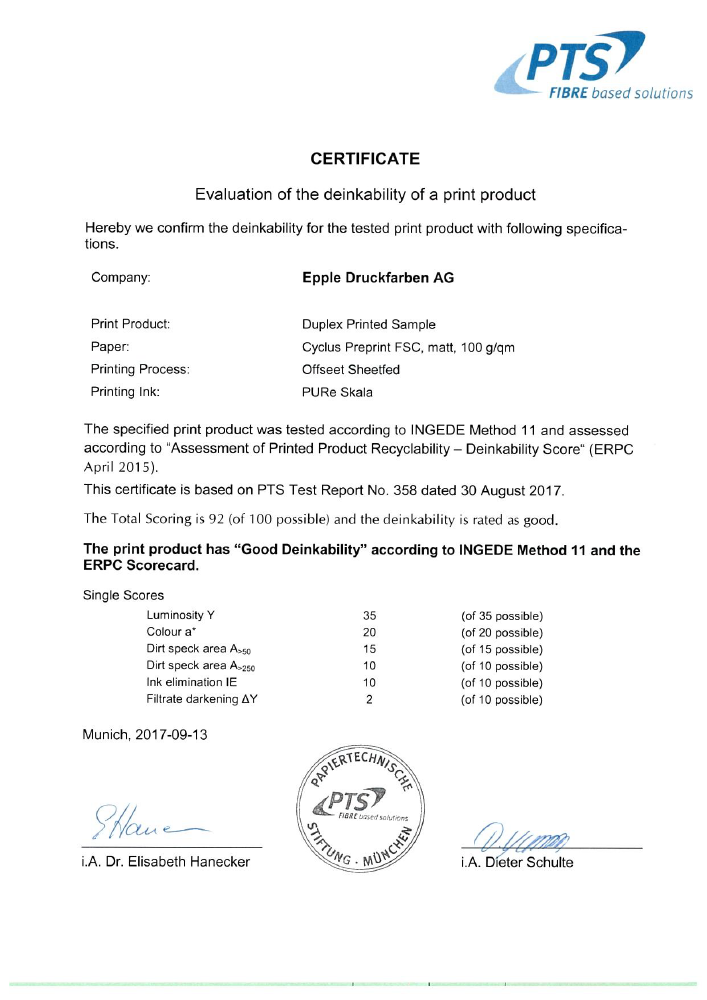

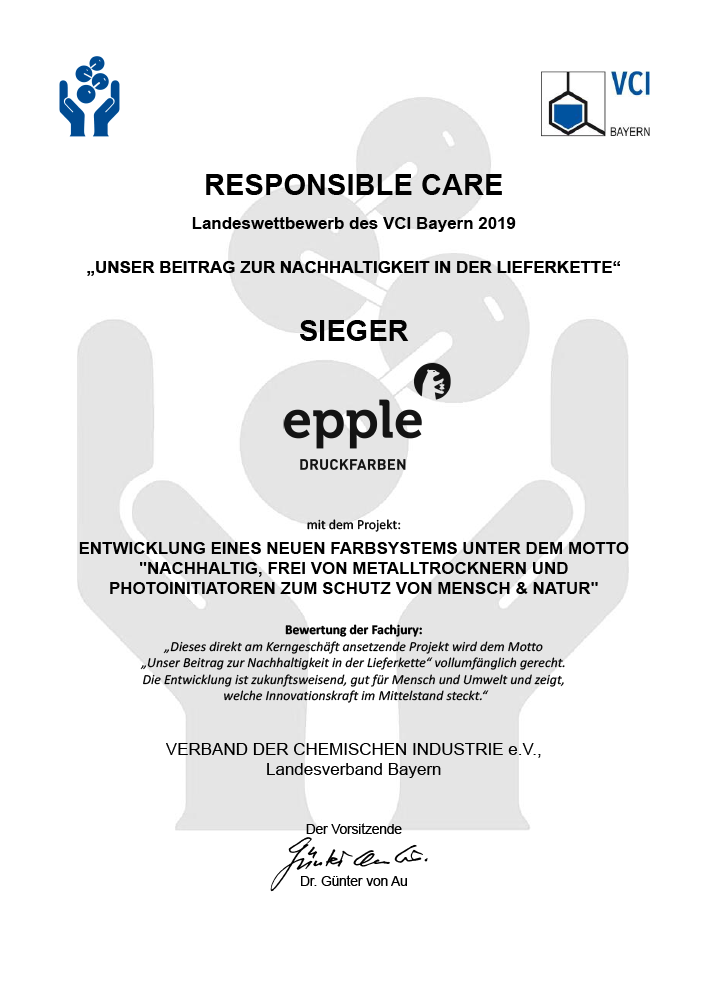

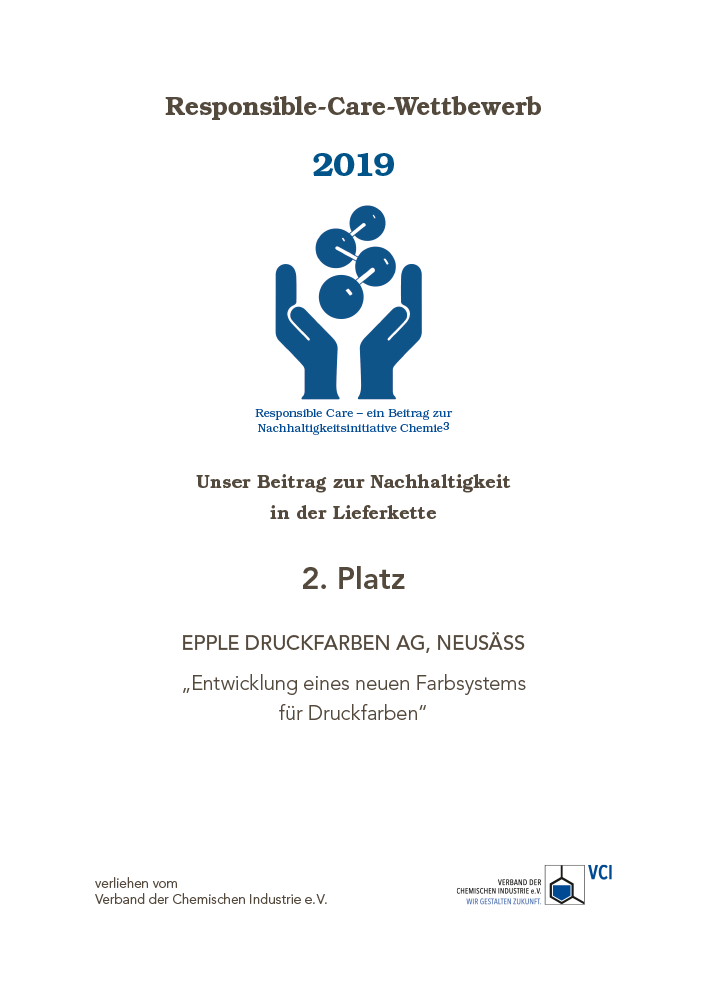

PURe certificates

prove excellent sustainability.

PURe® has a C2C Certified Material Health Certificate™ at the Platinum level.

PURe® won the Responsible Care State Competition of the Chemical Industry Association, Verband der Chemischen Industrie (VCI), in Bavaria in 2019.